Increasing the technological level of the company

M T J interior, s.r.o. | budget: 456 473,33 EUR

What was the project about ?

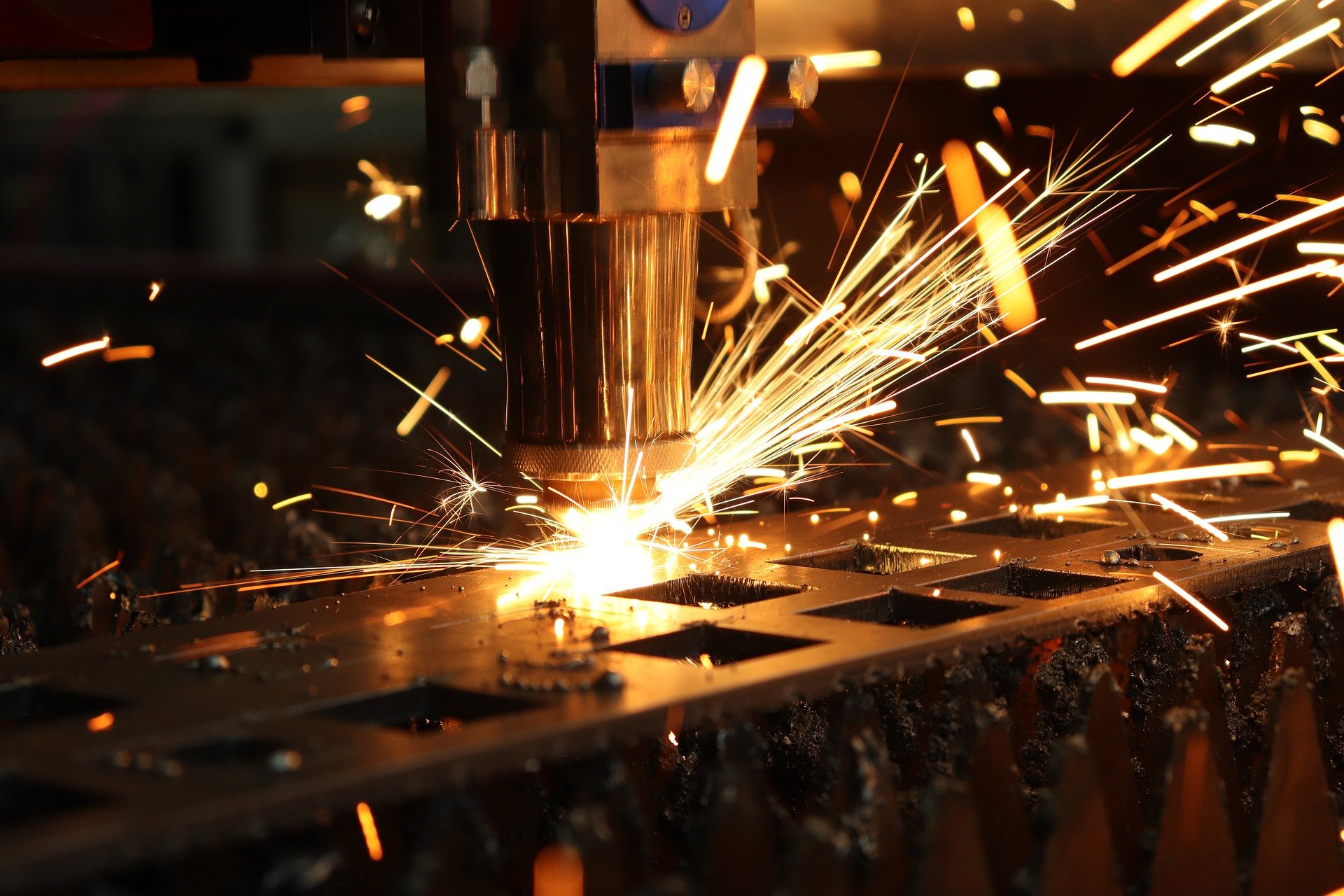

The company MTJ Interior, s.r.o. used another project to increase its technological level, which in addition followed the previous project of this company. The first project was mainly devoted to advancing the technical process of wood processing; this second project aimed to improve the technology in the metalworking part (laser cutting machine).

Idea and its formulation

The project is part of a comprehensive investment plan for innovation in the company. It was a natural follow-up to a previous project on which we collaborated. The main objective was to create a new process (service) for sheet metal laser cutting. Laser cutting is a high added value process that few companies in Slovakia are performing, and thus the delivery of these services depends on the spare capacity of suppliers.

Grant

The company took advantage of the favorable setting of the Operational Programme Research and Innovation, where it could apply for a grant (non-repayable financial contribution) repeatedly. The setup of project activities and expected results were defined as a follow-up from the implemented project in 2018.

Project processing

Due to the proven cooperation with the company on the previous project, we already knew each other's expectations and the project's process. The parameters that the new technology (laser cutting machine and CNC bending press) had to meet were defined by analyzing the market environment. The project logistic was set so that the client was no longer dependent on the capacities of external suppliers for laser cutting and could even provide these services to external customers.

Realization of the project

The suppliers of the technological units were selected through a public procurement process so that they were able to meet all the required parameters and not just offer the lowest price. The project's physical implementation schedule was harmonized for both technology units so that installation and commissioning had the most negligible impact on ongoing production.

Our comment

This project represents a collaborative model where a comprehensive investment plan in innovation was defined at the outset and progressively implemented in several phases/projects. It is, therefore, a model where Euro funds projects build on each other. The successful upgrade of the technological background to the industry 4.0 level will be followed by training projects and the procurement of software tools for the company's staff.