Development and production of a line for the production of hexagonal wire mesh

NOVAS MACHINERY s.r.o. | budget: 730 000,00 EUR

What the project was about

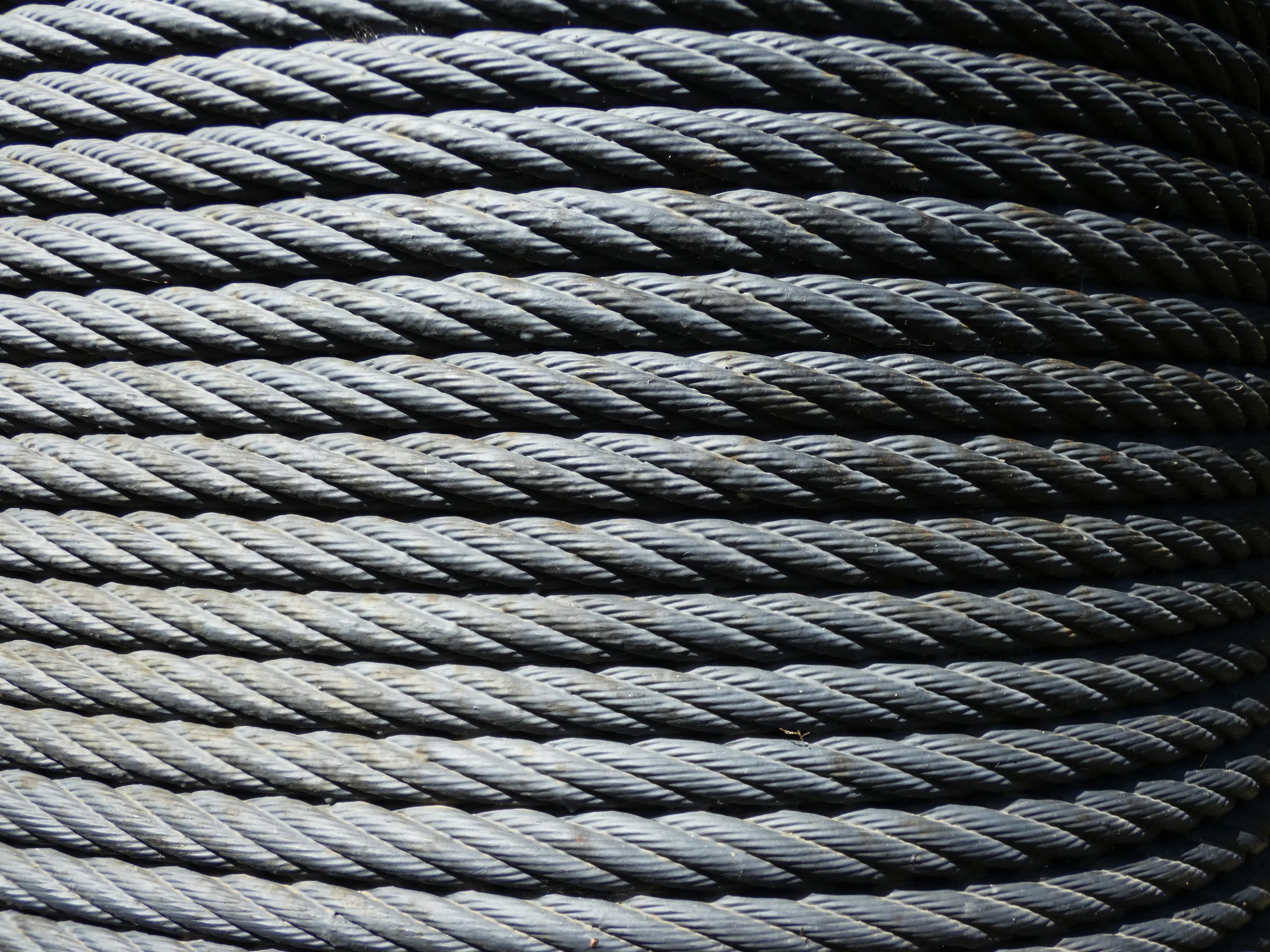

The project was successfully completed and the 3-year monitoring period within the project was also completed and documented. The main activity of the project was the creation of a unique technological unit for the processing of steel wire into a new product intended for the segment of stabilizing building elements. It was therefore a matter of launching trouble-free serial production of all variants of this product with the possibility of immediate application in practice, through already contracted cooperation. By fulfilling the project, it contributed to maintaining employment and the overall economic development of the company.

Idea and its formulation

The company's strategic intention was to develop a segment of production lines producing products for further use in construction. As part of this initiative, our client had a concrete idea of the new products and the technical design of the necessary production equipment. At this stage, they approached us in cooperation to analyze the possibilities of supporting this type of project from EU projects.

Grant for project realization

After precisely formulating the idea and intentions of the project (ASPHALTNET project), we found a suitable program - Operational Program Research and Innovation and a suitable call (product and process innovation), in which the company NOVAS MACHINERY s.r.o. was eligible with its project.

Project preparation

The whole technology and the product itself was unique and highly innovative so much that it was the only one of its kind in the engineering industry in Slovakia. As it was a matter of custom development and production, close communication between us and the client helped a lot in the elaboration of the project, which resulted in a precise definition of technical and technological requirements for the product. Subsequently, the process of processing the application for a non-refundable financial contribution for the company NOVAS MACHINERY s.r.o. was much simpler.

Project realization

During the processing of the NFP application, it was decided that the project will be implemented as a supplier. As the project was supported by public funds, the contractor had to be selected through the relevant procurement procedure, which was successful. The implementation of the project activities led to the innovation of the product and subsequently this product was launched on the market. The expected financial investment had a relatively quick return. It was a contribution to innovative technology and thus there was room for more efficient financial returns from the project, which also had a positive effect on the company's financial situation in the coming years since the project was implemented.

Our comment

This project was a great challenge in relation to the fact that the subject of the project was the custom development and production of unique engineering equipment. The technical specification and the planned implementation phases had to be defined so that the final ASPHALTNET product reached the required parameters and at the same time to give space to offer various solutions by individual suppliers. In close cooperation with the client, we managed to successfully manage all the challenges of this project and implement the project effectively. The relevant public procurement procedure was inspected by the Public Procurement Office without any identified deficiencies. The entire Eurofund project was also audited by the European Commission without any shortcomings identified.